The XR600R

Having a Siezure

All was not well with Steve's new ride. There were a few niggling problems with the bike, mainly related to running at idle. It ran rough and stalled regularly for no apparent reason. Steve almost managed to fix most of the problems by his usual method. He bashed everything in sight with a large rock until the offending bits worked properly, broke or fell off. With new throttle cables, intake manifold and main jet, the XR ran much bettererer (er), but it still wasn’t right.

Home

XR

1

2

3

4

Just as Steve thought he was getting most of the bugs ironed out of his new toy, he had a rude shock. The front tube (unknown vintage, possibly OEM) decided that it had had enough and went pop. Normally, tyres deflate in a slow and gentle fashion but this one literally exploded. Steve was halfway around a corner on a dirt road doing 70km/hr at the time. It wasn’t hugely fun, but he did manage to hold the bike upright and on the road (more luck than skill, obviously. Either that, or he was actually trying to crash). Apart from the tube, the only casualty was Steve’s underwear, which had to be thrown away. No way those stains were coming out. Steve wasn’t impressed. Studded leather G-strings aren’t cheap.

Shortly after the exploding front tube incident, the XR spat the dummy in a much more serious way. The motor seized, but contrary to our hopes and expectations, it didn’t lock up at high speed and throw Steve over the handlebars and into something solid. It was a pretty tame seizure as seizures go, and the only good thing about it was that it happened miles up in the scrub and Steve had to push the bike home. We laughed long and hard about that one.

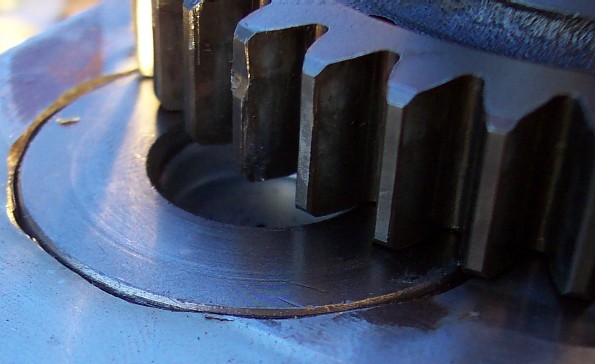

Once he’d recovered from the unexpected workout, Steve called the usual suspects and we all grabbed large rocks and proceeded to disassemble the motor. It all came apart pretty easily, and much to our surprise there wasn’t a great deal of internal damage. The culprit was quickly identified – the big-end bearing had gotten tired of being whacked on the head by 630cc of high-compression mumbo and self-destructed. The bits flew out at high speed and bounced off the crankcase and the bottom of the piston, leaving some pretty impressive impact craters in the process. Despite the damage, the case and piston were fine.

In fact, everything inside the engine was fine except the big-end bearing. It had been reduced to a handful of rollers and jagged debris scratching around between the crankpin and the rod. As you’d expect, with no bearing the rod didn’t rotate smoothly, and this was obviously the true cause of the idling problems that Steve had been struggling with. Everything else – gears, bearings, shafts, seals, cam, valves, timing chain… was all perfectly OK.

A quick phone call to Ballards Offroad, and a new rod kit was dispatched by overnight courier. Ballards are great. They’ve got heaps of go-fast bits for all kinds of off-road bikes, and their service is excellent. Their sales staff are piss funny, too, although I’m sure they don’t mean to be. Steve was exhorted to have a bike shop fit the rod kit instead of letting the Feral gang loose with the V-blocks and sledgie. “You can do it yourself or you can have it done properly” was the comment, and in hindsight it was hilariously off the mark. Unless, of course, they were talking about destroying the crankshaft.

Steve trundled off to A Certain Honda Dealer (no names, to protect the guilty) located somewhere in South-East Queensland with whom he’d done quite a bit of business. He asked them to fit the rod kit and they assured him that it would be no trouble. When he went to pick it up, however, he discovered that the crank had been sent to A Certain Engine Building Specialist (again, no names). Somewhere, somehow, the crankshaft was dropped or bashed into a workshop fitting and the counterbalancer drive gear was damaged. Much arguing and blame-shifting ensued (a million variations on “It’s not our problem, it’s the subbie’s problem” playing counterpoint to “Nah, mate, it was like that when we got it”), and the bike sat around in bits for three months while an agreement was reached. That took the efforts of the Qld Office of Fair Trading and the threat of legal action. All jolly good fun, and not at all frustrating. Honest.

[rant]

Anyone who works with customers on a day-to-day basis, please take note of the following: When you piss off a customer, they DON’T come back and do more business with you. They DO, however, tell all their mates about their bad experience. These mates then make up their own minds, and usually they don’t come back either. Customers don’t enjoy being taken for a ride or being treated like idiots and although most of them are upstanding, law-abiding citizens who will refrain from torching your house with your wife, kids and family pets inside… can you really afford to take the chance? Have a good think about that if you’re ever tempted to rip someone off or duck out of your legal responsibilities.

[/rant]

Anyway…

While the motor was in bits and waiting for a new crank, Steve took the opportunity to spend even more money and packed the camshaft off to Waggott Cams in NSW (4 Hugh St, Alstonville, NSW, 2477 Ph:02-6628 3795, Fax:02-6628 1620). Peter Waggott grinds cams for a whole variety of vehicles, including aircraft, Ballards-enhanced XRs and the odd V8 Supercar. Peter's workmanship and service are second to none. Steve had his camshaft back in a week, all shiny and new-looking and lumpier than a troglodyte with mumps.

When an agreeement was finally reached with A Certain Honda Dealer, a replacement second-hand crankshaft was sourced from Al’s Bikes & Bits and Joe Marshall pressed on the new crankpin and rod. Joe has an impressive collection of 8- and 9-second Suzuki drag bikes and spends a lot of his time repairing the damage done to crankshafts by A Certain Engine Building Specialist. Joe is a great bloke and he does superb work. Steve’s new crank was no exception, and even though it was completely butchered during the reassembly process, it was perfectly factory-spec for a little while.

The XR mill went back together fairly easily, all things considered. It was especially easy for two-thirds of the Feral team, ‘coz we just left Steve to get on with it. It was really amusing listening to his frenzied phone calls for help:

“Can you pop over and give me a hand, guys? I’ve just dropped the gearbox and there are bits all over the garage floor. I think Richard pulled it apart and I’ve got no idea how it goes back together… guys? Hello?”

“Neil, pick up if you can hear me… I’ve kinda got my hand jammed in the block while I was trying to get the barrel on and I can’t get it out… and it really hurts. I don’t wanna call the ambos again ‘coz they’ll probably bring the video camera this time…”

“Ahhh… Richard, can I borrow your helicoil kit again? I’ve just stripped another thread…”

According to Steve it wasn’t very easy installing the crankshaft without a press or a selection of Honda factory tools or even a spare pair of hands, but a big hammer and persistence got there in the end. True, by the end of the “installation” a few big chunks of metal had spalled off the bearings, the crank and the cases, but it was all in one piece and it rotated (admittedly with loud crunching noises).

Eventually, the many assorted large pieces and sub-assemblies were bolted together to form something that resembled an engine. Steve was able to collect all the left over parts (four nuts of different sizes, a spring, half a dozen washers, two gears, a bearing and a strange rod-type thingy we couldn’t identify), tighten the last bolt to our special “Feral-spec” torque (until it strips, then back off half a turn) and kick the XR in the guts. It took a while and generated some distressing noises (some from Steve, some from the bike) but eventually the wheezing, swearing and occasional pop-splutter were drowned out by that distinctive thumping ‘zorst note and a loud hashing sound from the top end. That’s only to be expected when you forget to put any oil in there. Oops. With the addition of some slippery stuff, the nasty grinding-type sounds slowly faded and the thumping got even louder. The mighty XR was back!